You are an old man who wants to buy a 180-ton injection molding machine. The cost of such a machine can vary based on several factors. This guide intends to examine the various factors that influence the cost of an injection molding machine. This should help you set your expectations when considering such a purchase.

Price-wise, the cost of an injection molding machine depends on so many different things that can affect the price. Type of machine, size of the machine, brand of the machine, special features it offers, etc. A price of an 180 ton injection molding machine comes to you with a lot of things to see and consider.

The machine's brand can play a large role in the price. Some brands are so trusted & popular among many people. Due to their reputation, these manufacturers can raise the price on their machines. But on the flip side, unknown brands could also have the same machines at cheaper rates. You should compare other brands to determine which one provides the most bang for your buck.

Machine dimensions is another main aspect that affects price. An injection molding machine is of medium-to-large size at 180 tons. Its more substantial size does come with a price tag, however, and typically such machine are more pricey than smaller machines. Size can also be adjusted to what works best for your projects.

The average price will also depend on the type of injection molding machine you choose. Hydraulic machines, all-electric machines, and hybrid machines are just a few of the various types. Different kinds of furniture would have different features that may alter the price. For instance, hydraulic machines may be cheaper than all-electric machines due to technology and efficiency variations.

Lastly, the machine can also be more expensive due to its features. Some features that could drive the cost of a 180-ton injection molding machine up higher include automation, custom options and precise controls. Custom options can be used to modify the machine to fit your particular needs, and automation can also be utilized to make the machine easier to use and operate.

170 ton injection molding machine price vs specificationYou should consider the price and the features that you are going to get when you are about to purchase a 180-ton injection molding machine. Compaing prices between the brands will help you to score a great deal. It will also determine how well each machine will serve you based on some of the features they come with. Comparing across models can be useful, so it may help to make a list of the features that are most important to you.

Our team is committed to providing outstanding customer service and satisfaction throughout the lifecycle of our equipment. Our 180 ton injection moulding machine price to provide rapid personalized assistance. If it's maintenance troubleshooting or other issues we actively cooperate with our customers to promptly solve any problems they might face. Our butler service method ensures that our customers receive continuous assistance and support establishing a long-lasting partnership built on trust and dependability.

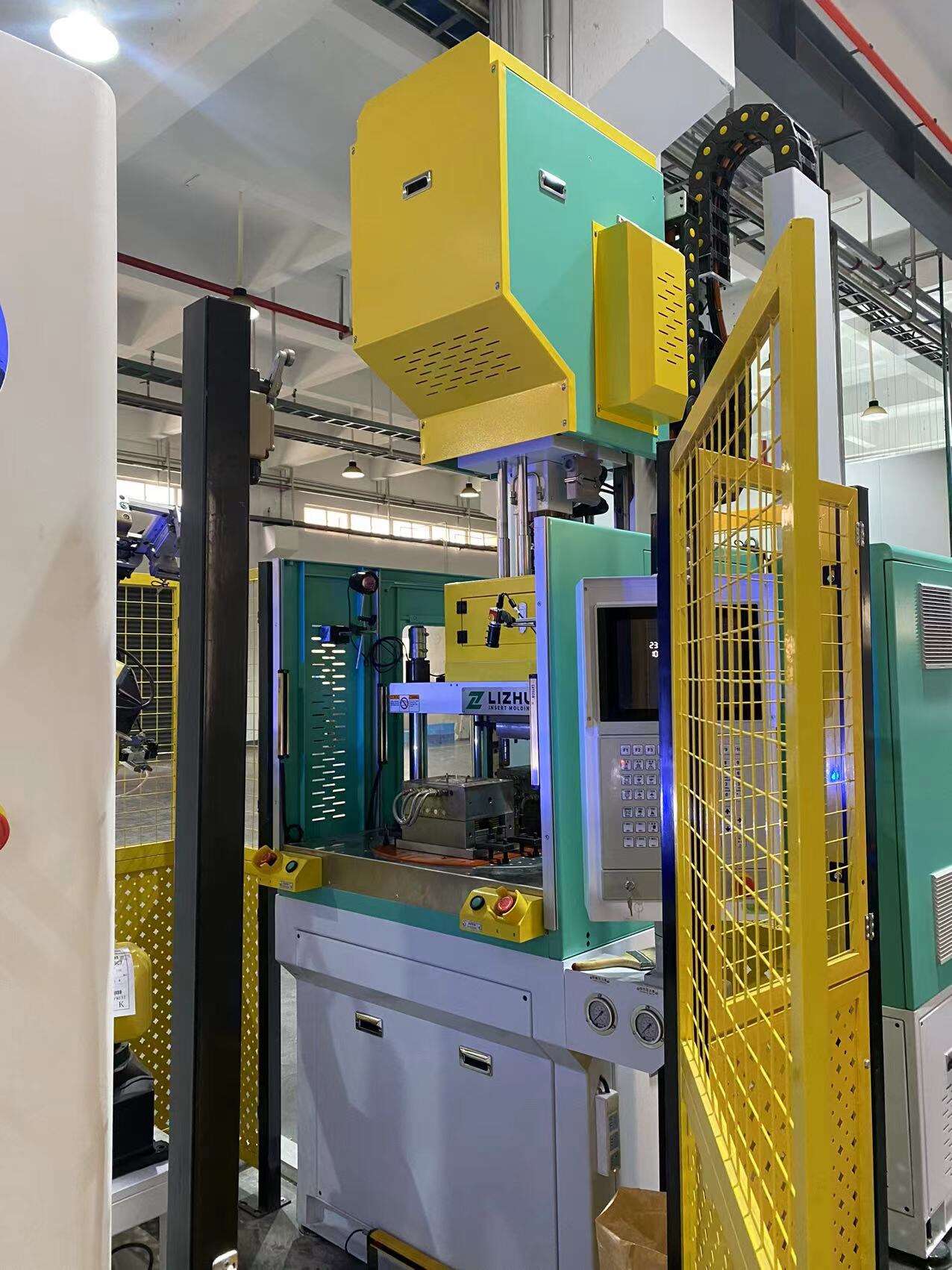

Our customers appreciate the deep customization we provide. We realize that each project is unique which is why we provide a custom single-stop solution that is 180 ton injection moulding machine price. From the initial idea to the final implementation We work closely with our customers making sure the vision they have in mind is achieved. We currently have various models of standard machines sliding table machines multi-color machines and rotary machines up to 2000 tons. They are widely used in electronics telecommunications and aerospace industries as well as in home appliances everyday necessities, automotive, semiconductor packaging and medical. Our ability to execute turnkey projects assures a seamless and efficient service for our customers.

Our solutions are based on customer wants. We integrate advanced technology. We are 180 ton injection moulding machine price and trends in the industry of injection molding machines. We increase the efficiency of our machines as well as their efficiency by integrating innovative features and components. Our commitment to ongoing service after sales ensures that we are able to optimize our solutions throughout their entire lifespan.

With more than 33 years of experience in the field of injection molding machines We have amassed a wealth of understanding and 180 ton injection moulding machine price. We also have a huge 20,000 square-meter research and design center. Our team is comprised of highly skilled professionals who are knowledgeable of the latest technological advances and best practices in the field. With continuous technological innovation, LIZHU Machinery has obtained more than 100 patents on designs and utility models, creating itself as a nationwide high-tech business. Our products have reached international advanced levels, and have been certified by TUV CE UL and ISO 9001.