Hi there! We will learn about UK vertical plastic injection machines today. These machines are indeed very important because they produce many different products in the form of plastic, through the manufacturing process. So, How do these machines work? Why are they so special?

When we speak of precision, we mean doing something painstakingly and therefore exactly. It’s like if you drew a picture and want to make sure all the lines are straight. Plastic Injection Machines Vertical injection machines are designed to create plastic. The plastic item is interlocked perfectly and thus works well. Just like assembling a puzzle that requires placement of each piece.

To "revolutionize" is to alter something on a grand and exciting scale. The keyword vertical plastic injection machines have told you what you are about to read. They make it possible to manufacture plastic products faster and better than ever. Let us say you have a toy factory. With these machines you can produce many toys in less time and with improved quality. This method allows you to make more toys in less time and with less waste, meaning you don't throw away material. This is amazing, since it helps save money, and it is also better for the environment!

When we say "high-quality results", we literally mean this, which is that the vertical machine will make plastic items that are very strong, durable and all the same looking very well. It’s like that cookie-baking analogy. If you use great ingredients and follow the recipe closely, you make delicious cookies that everyone loves! These machines use the latest technology and produces nearly perfect plastic products. Which means that if you are looking to produce a lot of plastic bits and bobs such as plastic containers or even plastic toys, the best vertical machine in the UK will have you covered!

"Advanced" means you are creating something new using the latest tools and ideas. Advanced vertical plastic injection machines are produced for higher and better efficiency work. This allows you to produce more plastic objects with relative ease, and they'll all be good-quality! These machines make factories able to do things faster, much like how superheroes can get things done quicker.

22 comments for Industry-leading" means being the best in the business. That is the luxury of having top-tier vertical machines in the UK! These equipment are the best of the best, as they use cutting-edge tools and techniques to create durable and visually satisfying plastic products. And in order to be on top of your competitors you must have the best machines - thus you may opt to have your machinery from Lizhu Machinery. Our machines make sure you have the best quality in your products and that you are different from your competition.

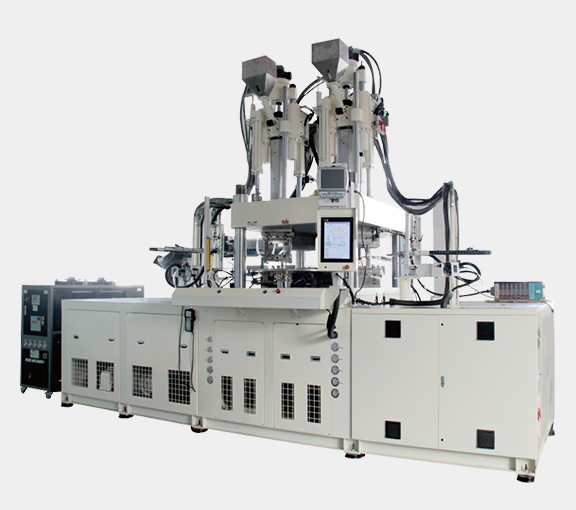

We have over 33 years experience in the world of injection molding machine. We have vertical plastic injection machine uk and expertise. In addition, we have a 20,000 square meter research and development centre. Our team is made up of highly experienced professionals who are knowledgeable about the latest practices in the industry and technological advances. LIZHU Machinery, through continuous technological innovation and advancement has earned more than 100 patents and inventions, as well as utility models, which has established it as an innovative national company in high-tech. Our products have reached the highest levels of international excellence, and are approved by TUV CE UL and ISO 9001.

We're vertical plastic injection machine uk into our solutions to meet the current needs of our clients. We are always up to date with most current innovations and trends within the injection molding machine industry. Through sourcing and integrating cutting-edge elements and capabilities we enhance the performance and efficiency of our machines. Our commitment to ongoing service after sales ensures that we can improve our products throughout their entire lifespan.

Our clients are vertical plastic injection machine uk. We know that each project is different so we provide a one-stop solution to suit individual needs. From the beginning of the concept to the finalization we collaborate closely with our customers making sure the vision they have in mind is achieved. We currently have various models of standard machines that include sliding table machines multi-color rotary machines as well as rotary machines with capacities of up to 2000 tonnes. These machines are extensively used in the electronics telecom and aerospace sectors as well as in appliances for homes everyday needs and automotive, semiconductor packaging and medical. Turnkey projects are an excellent way to ensure a smooth and efficient process.

Our team is committed providing superior customer services and vertical plastic injection machine uk. Our team of professionals can be reached 24/7 to provide prompt personal assistance. When comes to troubleshooting maintenance or any other issues we are constantly working with clients to quickly address any issues they encounters. Our butler services method ensures that clients receives continuous assistance and supports in establishing lasting partnership based trust and reliability.