Do you want to know what plastic objects are made out of? For example, one method to manufacture plastic items is actually with the aid of a horizontal plastic injection machine. This machine functions by heating up tiny plastic pellets until they reach a hot and gooey consistency. Next it pours this hot plastic into a mold; that’s a shaped container that will turn it into a specific product. This process is vital for the production of a plethora of items in our daily lives.

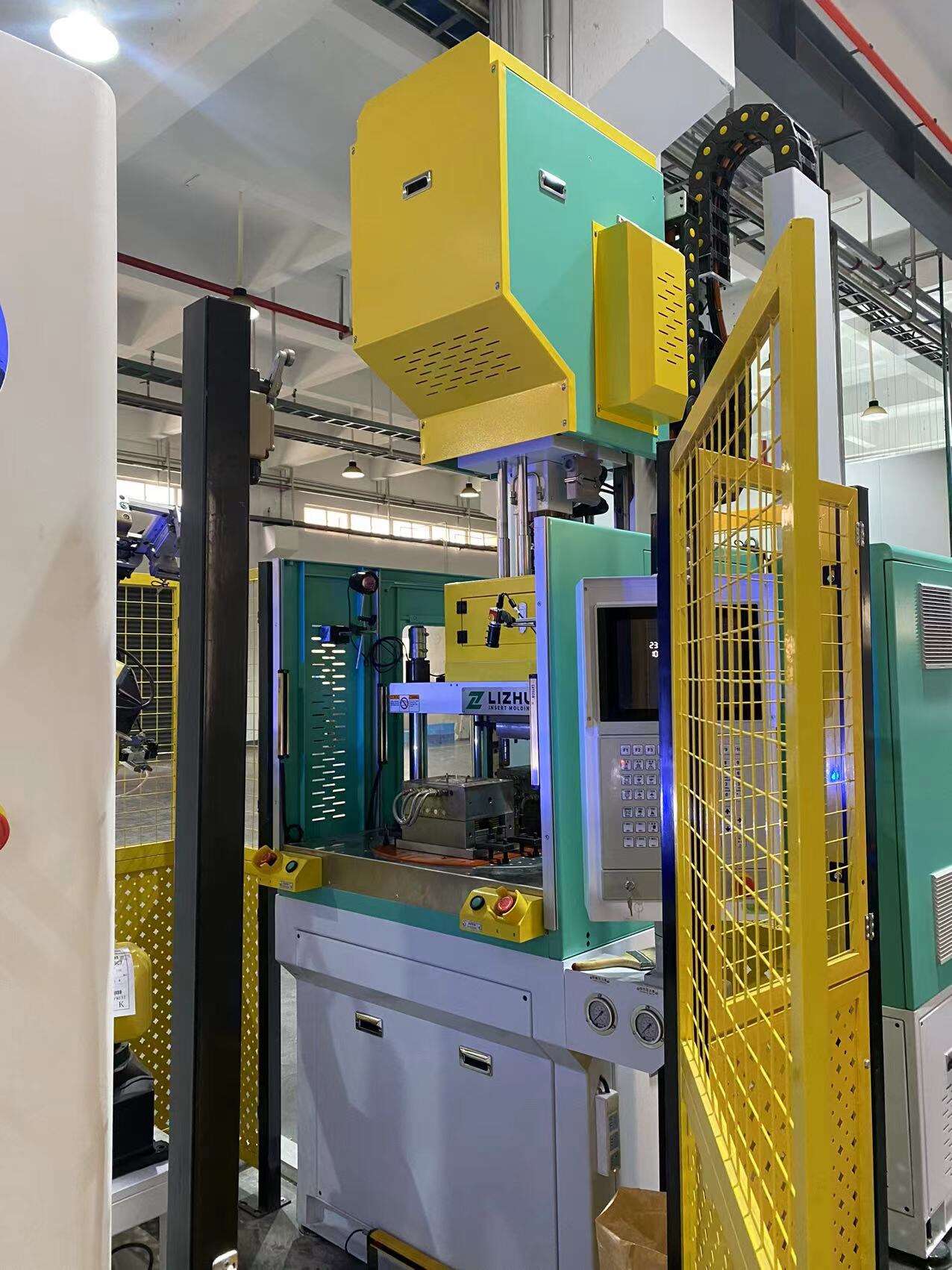

A lot of high-quality vertical injection machines are produced in Spain. They are produced in companies, such as LIZHU MACHINERY, who manufacture these types of machines. They have provided injection machines for more than 20 years. Therefore, they know a lot about how to improve these machines. LIZHU MACHINERY creates bespoke machines for numerous international companies across various segments. Their products have applications everywhere, from toys to medical equipment. Let’s find out what they make and how their machines operate!

So, precision is a word that you might say when something is very careful and exact. In manufacturing of plastic products, it plays a major role as it helps make sure that the process is right and same every time. The vertical injection machines from LIZHU MACHINERY has a special control system. This guidance ensures that the plastic flows into the mold at the precise speed, pressure, and location. This ensures the hot plastic fills the mold correctly, without issues like air bubbles and getting warped.

That is one of the exciting things about the LIZHU MACHINERY's machines; these machines are customizable, which means that they can be changed to suit the unique needs of their clients. LIZHU MACHINERY can customize and design machines work best for the client, depending on what the client needs. For example, they adjust the size and shape of the mold, how hard it closes down, and how much plastic to inject into the mold. Thanks to this degree of customisation, businesses can manufacture a broad range of products to meet their unique needs.

LIZHU MACHINERY machines are not just customizable, but they are also fast and energy-efficient. Their hydraulic servo system enables fast operation of the machines. That lip service means less waiting time between doing various items, and thus enables more prompts to do multiple things in far less time. They use less oil and produce less noise and heat, saving energy as well. This creates a better working environment as well as lowers operational costs for the companies operating these machines.

LIZHU MACHINERY machines are also user friendly. With simple controls and screens that enable workers to adjust settings and monitor what’s happening, the machines are easier to use than traditional motors. The machines provide critical information, such as temperature, pressure and speed, in a clear, easy-to-read fashion, whether the information is displayed on a touch screen or a digital display. Due to this user-friendliness, it has become easier for the operators to successfully operate the machines.

LIZHU MACHINERY supply machines that also have many safety measures to ensure the protection of the workers using the machinery. They also feature emergency stop buttons that allow the device to shut down quickly if something goes wrong. They also have safety doors and interlocks that help prevents accidents and injuries from occurring. All such functionalities together aid in streamlining the production process, minimizing errors, and maximizing productivity.

Our clients are vertical plastic injection machine Spain. We know that each project is different so we provide a one-stop solution to suit individual needs. From the beginning of the concept to the finalization we collaborate closely with our customers making sure the vision they have in mind is achieved. We currently have various models of standard machines that include sliding table machines multi-color rotary machines as well as rotary machines with capacities of up to 2000 tonnes. These machines are extensively used in the electronics telecom and aerospace sectors as well as in appliances for homes everyday needs and automotive, semiconductor packaging and medical. Turnkey projects are an excellent way to ensure a smooth and efficient process.

We have over 33 years experience in the vertical plastic injection machine Spain. This has given us the knowledge and experience. We also have a 20,000 square-meter design and research center. Our team is comprised of highly experienced professionals that are proficient in technology's most efficient practices and developments. Through constant technological innovation, LIZHU Machinery has obtained more than 100 patents on inventions and utility models, becoming a leading national high-tech enterprise. Our products are at international advanced levels and have been approved by TUV, CE, UL as well as ISO 9001.

Our team is committed to providing outstanding customer service and satisfaction throughout the lifecycle of our equipment. Our vertical plastic injection machine Spain to provide rapid personalized assistance. If it's maintenance troubleshooting or other issues we actively cooperate with our customers to promptly solve any problems they might face. Our butler service method ensures that our customers receive continuous assistance and support establishing a long-lasting partnership built on trust and dependability.

Our vertical plastic injection machine Spain. We incorporate cutting-edge technology. We stay up-to-date with the most current innovations and trends within the field of injection molding machines. By sourcing and integrating cutting-edge components and features we improve the efficiency and performance of our machines. In addition our commitment to a continual after-sales service guarantees that our products remain optimized throughout their lifecycle.